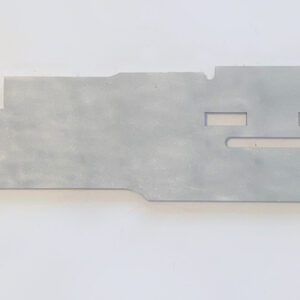

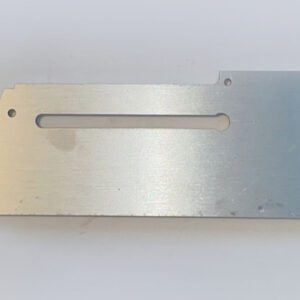

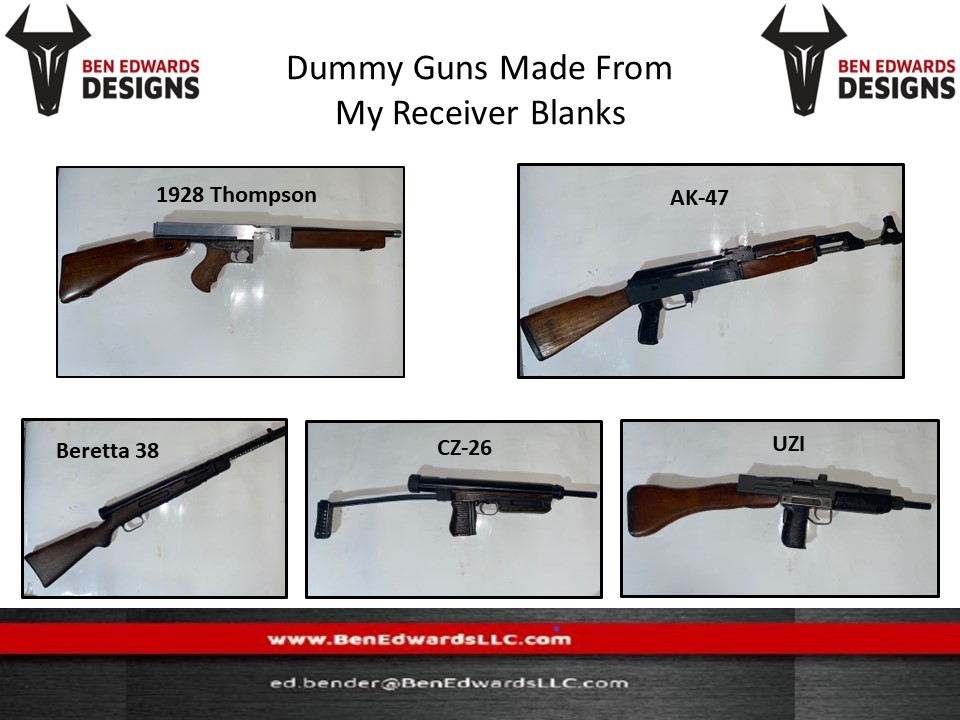

Description

This M1 Garand pattern was original owned by Sarco INC and has been in production for over 30 years. These casting are made from 8620 steel. These castings should be considered as non functional paperweight and should not be used to make a functional weapon This is a net casting, NO FFL Needed.

Background

The M1 Garand was made in large numbers during World War II; approximately 5.4 million were made. They were used by every branch of the United States military. The rifle generally performed well. General George S. Patton called it “the greatest battle implement ever devised.” The typical opponent of a US soldier during World War II was usually armed with a slower-firing bolt-action rifle (e.g. the Karabiner 98k for Germany, the Carcano M1891 for Italy, and the Type 38 or Type 99 Arisaka rifle for Japan). The impact of faster-firing infantry small arms in general soon stimulated both Allied and Axis forces to greatly increase their issue of semi- and fully automatic firearms then in production, as well as to develop new types of infantry firearms. Many M1s were repaired or rebuilt after World War II. While U.S. forces were still engaged in the Korean War, the Department of Defense decided more were needed. Springfield Armory ramped up production, but two new contracts were awarded. During 1953–56, M1s were produced by International Harvester and Harrington & Richardson in which International Harvester alone produced a total of 337,623 M1 Garands. A final, very small lot of M1s was produced by Springfield Armory in early 1957, using finished components already on hand. Beretta also produced Garands using Winchester tooling.

Technical Information

| In service | 1936–1957 (as the standard U.S. service rifle) |

| 1940s–present (other countries) | |

| Designer | John C. Garand |

| Designed | 1928 |

| Manufacturer | Springfield Armory |

| Winchester | |

| Harrington & Richardson | |

| International Harvester | |

| Beretta | |

| Breda | |

| F.M.A.P. | |

| Springfield Armory, Inc. (civilian) | |

| Unit cost | About $85 (during World War II) (equivalent to $1,330 in 2021) |

| Produced | 1934–1957 |

| No. built | 5,468,772 |

| Variants | See Variants |

| Specifications | |

| Mass | 9.5 lb (4.31 kg) to 11.6 lb (5.3 kg) |

| Length | 43.5 in (1,100 mm) |

| Barrel length | 24 in (609.6 mm) |

| Cartridge | .30-06 Springfield (7.62×63mm) |

| 7.62×51mm NATO (.308 Winchester) (Postwar use by U.S. Navy) | |

| Action | Gas-operated, closed rotating bolt |

| Rate of fire | 40–50 rounds/min |

| Muzzle velocity | 2,800 ft/s (853 m/s) |

| Effective firing range | 500 yd (457 m) |

| Feed system | 8-round en bloc clip, internal magazine |

| Sights | Rear: adjustable aperture |

| Front: wing protected post | |

Design

The M1 rifle is a .30 caliber, gas-operated, 8 shot clip-fed, semi-automatic rifle. It is 43.6 inches (1,107 mm) long and it weighs about 9.5 pounds (4.31 kg). The M1’s safety catch is located at the front of the trigger guard. It is engaged when it is pressed rearward into the trigger guard, and disengaged when it is pushed forward and is protruding outside of the trigger guard. The M1 Garand was designed for simple assembly and disassembly to facilitate field maintenance. It can be field stripped (broken down) without tools in just a few seconds. The rifle had an iron sight line consisting of rear receiver aperture sight protected by sturdy “ears” calibrated for 100–1,200 yd (91–1,097 m) in 100 yd (91 m) increments. The bullet drop compensation was set by turning the range knob to the appropriate range setting. The bullet drop compensation/range knob can be fine adjusted by setting the rear sight elevation pinion. The elevation pinion can be fine adjusted in approximately 1 MOA increments. The aperture sight was also able to correct for wind drift operated by turning a windage knob that moved the sight in approximately 1 MOA increments. The windage lines on the receiver to indicate the windage setting were 4 MOA apart. The front sighting element consisted of a wing guards protected front post.

Reviews

There are no reviews yet.