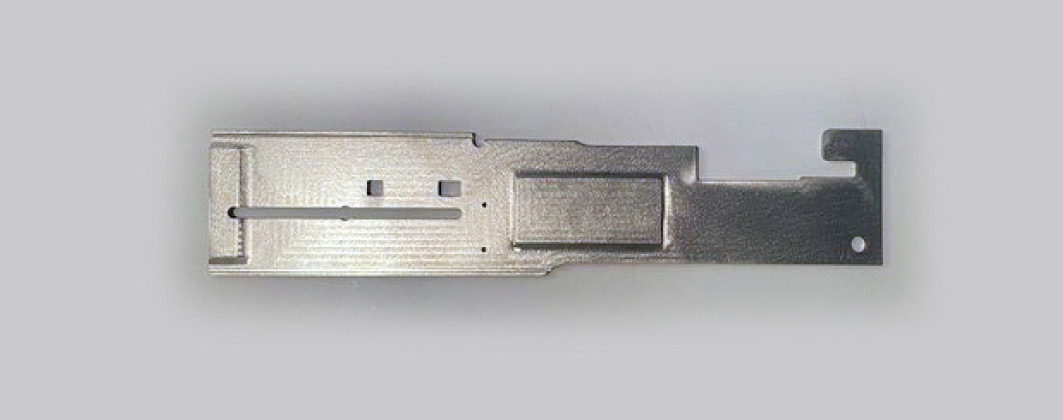

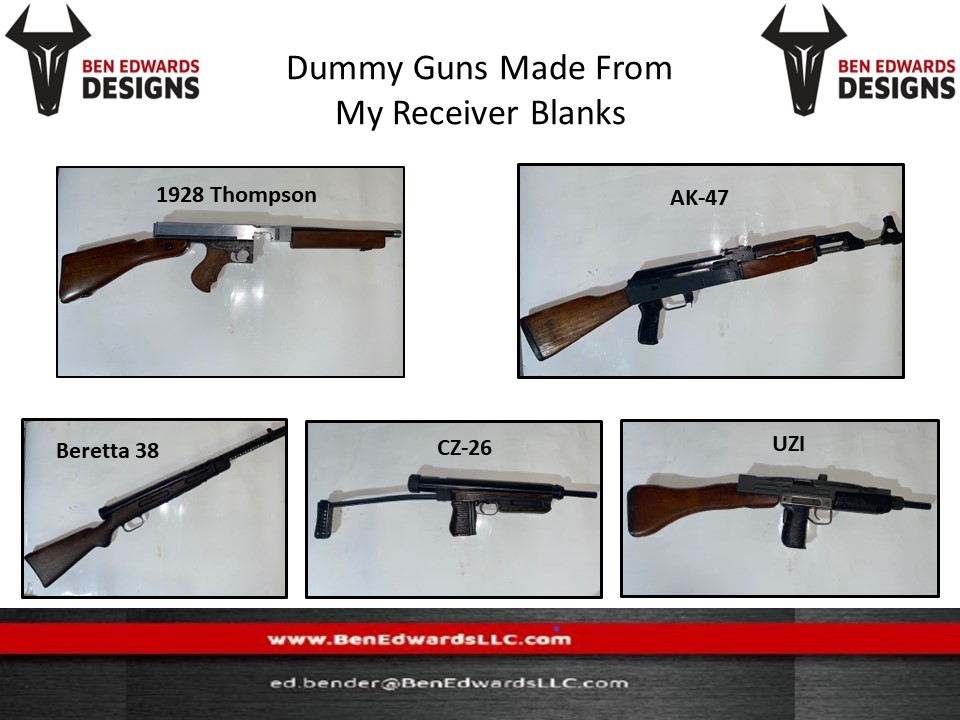

Description

Plate is manufactured from 4140 steel alloy plate that is stressed relieved and CNC machined to original military specifications. We do not use a laser or waterjet to cut the profile like other manufacturers. Our plates are 100% CNC machined for smooth edges like the original. A raised island .065″ is exposed on the inside of the plate to prevent insertion of machine gun parts. Plate has all the machine work completed with regards to profile, slots and charge handle. Requires some holes to be drilled or reamed to final size for completion. Also requires some hand filing to match the plate to your kit for age and wear.

NO FFL or paperwork is required.

Background

Machine guns were heavily used in World War I, and weapons of larger than rifle caliber began appearing on both sides of the conflict. The larger rounds were needed to defeat the armor that was being introduced to the battlefield, both on the ground and in the air. Germany introduced the Junkers J.I aircraft, whose armor could render ineffective aircraft machine guns that used conventional rifle ammunition such as the .30-06 Consequently, the American Expeditionary Force’s commander General John J. Pershing asked for a larger-caliber machine gun. Pershing asked the Army Ordnance Department to develop a machine gun with a caliber of at least 0.50 inches (12.7 mm) and a muzzle velocity of at least 2,700 feet per second (820 m/s).

Around July 1917, John Browning started redesigning his .30-06 M1917 machine gun for a larger and more powerful round. Winchester worked on the cartridge, which was a scaled-up version of the .30-06. Winchester initially added a rim to the cartridge because the company wanted to use the cartridge in an anti-tank rifle, but Pershing insisted the cartridge be rimless. The first .50-caliber machine gun underwent trials on 15 October 1918. It fired at less than 500 rounds per minute, and the muzzle velocity was only 2,300 ft/s (700 m/s). Cartridge improvements were promised. The gun was heavy, difficult to control, fired too slowly for the anti-personnel role, and was not powerful enough against armor.

While the .50-caliber was being developed, some 13.2×92mmSR Mauser 1918 T-Gewehr anti-tank rifles and its ammunition were captured. The 13.2mm German rounds had a muzzle velocity of 2,700 ft/s (820 m/s), an 800 gr (52 g) bullet, and could penetrate armor 1 in (25 mm) thick at a range of 250 yd (230 m). Winchester improved the .50 caliber round to have similar performance. Ultimately, the muzzle velocity was 2,750 ft/s (840 m/s).

Technical Information

| Place of origin | United States |

| In service | 1933–present |

| Production history | |

| Designer | John M. Browning |

| Designed | 1918 |

| Manufacturer | Current |

| Fabrique Nationale | |

| General Dynamics | |

| Ohio Ordnance Works Inc. | |

| U.S. Ordnance | |

| Former | |

| Manroy Engineering | |

| Sabre Defence Industries | |

| Colt’s Patent Firearms Manufacturing Company | |

| High Standard Firearms | |

| Savage Arms Corporation | |

| Buffalo Arms Corporation | |

| General Motors Corporation | |

| Frigidaire | |

| AC Spark Plug | |

| Saginaw Steering Gear Division | |

| Brown-Lipe-Chappin Divisions | |

| Kelsey Hayes Wheel Company | |

| Springfield Armory | |

| Wayne Pump Company | |

| ERMCO | |

| Ramo Manufacturing | |

| Rock Island Arsenal | |

| Produced | 1921–present (M2HB/M2A1) |

| No. built | 3 million |

| Specifications | |

| Mass | 38 kg (84 lb) |

| 28 kg (62 lb) (AN/M2) | |

| 58 kg (128 lb) with tripod and traverse and elevation mechanism (T&E) | |

| Length | 1,654 mm (65.1 in) |

| 1,429 mm (56.3 in) (AN/M2) | |

| Barrel length | 1,143 mm (45.0 in) |

| 910 mm (35.8 in) (AN/M2) | |

| Cartridge | .50 BMG (12.7×99mm NATO) |

| Action | Short recoil-operated |

| Rate of fire | 450–600 rounds/min (M2HB) |

| 750–850 rounds/min (AN/M2) | |

| 1,200–1,300 rounds/min (AN/M3) | |

| Muzzle velocity | 2,910 ft/s (890 m/s) for M33 ball |

| Effective firing range | 1,800 m (2,000 yd)[7] |

| Maximum firing range | 7,400 m (8,100 yd) |

| Feed system | Belt-fed (M2 or M9 links) |

Design

The M2 has an effective range of 1,830 metres (2,000 yd) and a maximum effective range of 2,000 metres (2,200 yd) when fired from the M3 tripod. In its ground-portable, crew-served role as the M2HB, the gun itself weighs 84 pounds (38 kg) and the assembled M3 tripod another 44 pounds (20 kg). In this configuration, the V-shaped “butterfly” trigger is located at the very rear of the weapon with a “spade handle” hand-grip on either side of it and the bolt release in the center. The spade handles are gripped and the butterfly trigger is depressed with one or both thumbs. Recently, new rear buffer assemblies have used squeeze triggers mounted to the hand grips, doing away with the butterfly triggers.

When the bolt release is locked down by the bolt latch release lock on the buffer tube sleeve, the gun functions in fully automatic mode. Conversely, the bolt release can be unlocked into the up position resulting in single-shot firing (the gunner must press the bolt latch release to send the bolt forward). Unlike virtually all other modern machine guns, it has no safety (although a sliding safety switch has recently been fielded to USMC armorers for installation on their weapons and is standard-issue for the U.S. Army for all M2s). Troops in the field have been known to add an improvised safety measure against accidental firing by slipping an expended shell casing under the butterfly trigger. The upgraded M2A1 has a manual trigger block safety.

Because the M2 was designed to operate in many configurations, it can be adapted to feed from the left or right side of the weapon by exchanging the belt-holding pawls, and the front and rear cartridge stops (three-piece set to include link stripper), then reversing the bolt switch. The operator must also convert the top-cover belt feed slide assembly from left to right-hand feed as well as the spring and plunger in the feed arm. This will take a well-trained individual less than two minutes to perform.

The charging assembly may be changed from left to right-hand charge. A right-hand charging handle spring, lock wire, and a little “know-how” are all that is required to accomplish this. The M2 can be battle-ready and easily interchanged if it is preemptively fitted with a retracting slide assembly on both sides of the weapon system. This eliminates the need to have the weapon removed from service to accomplish this task.

At some point during World War 2, the Frankford Arsenal developed a squeeze bore version of the M2HB which reduced the bullet size from .50 to .30 caliber.

Reviews

There are no reviews yet.