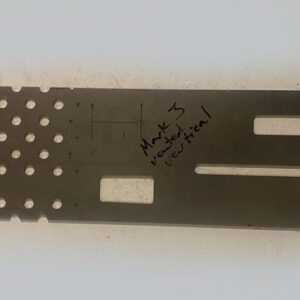

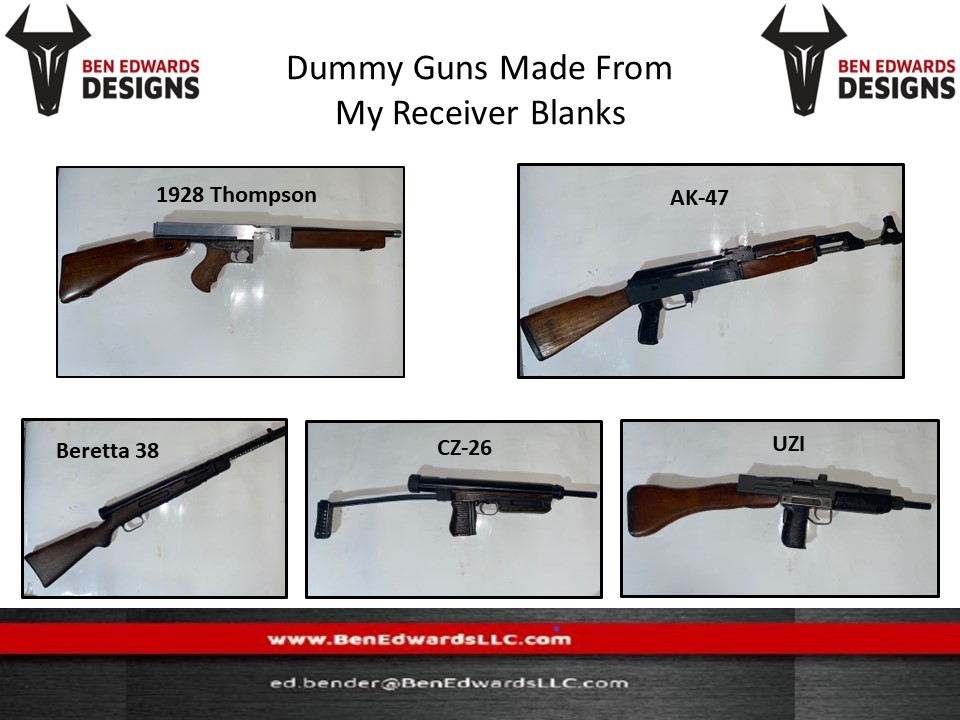

Description

This 6061 aluminum Mp40 dummy receiver has the correct diameter to accept the receiver extension. The correct inside diameter for the receiver extension and the lugs in the back of the receiver to interlock with the stock assembly.

NO FFL or paperwork is required.

Background

Designed in 1938 by Heinrich Vollmer with inspiration from its predecessor the MP 38, it was heavily used by infantrymen (particularly platoon and squad leaders), and by paratroopers, on the Eastern and Western Fronts as well as armoured fighting vehicle crews. Its advanced and modern features made it a favorite among soldiers and popular in countries from various parts of the world after the war. It was often called “Schmeisser” by the Allies, after Hugo Schmeisser, who designed the MP 18, although he was not involved in the design or production of the MP 40. The weapon’s other variants included the MP 40/I and the MP 41. From 1940 to 1945, an estimated 1.1 million were produced by Erma Werke.

Technical Information

| In service | 1939–1945 (Nazi Germany) |

| 1940–present (other countries) | |

| Production history | |

| Designer | Heinrich Vollmer |

| Berthold Geipel | |

| Designed | 1940 |

| Manufacturer | Steyr-Mannlicher |

| Erma Werke | |

| Haenel | |

| Unit cost | 57 ℛℳ (1940) |

| 250 EUR current equivalent | |

| Produced | 1940–1945 (MP 40) |

| No. built | 1,100,000 (estimated) |

| Variants | MP 36 |

| MP 38 | |

| MP 40 | |

| MP 40/1 | |

| MP 41 | |

| Specifications | |

| Mass | 3.97 kg (8.75 lb) |

| Length | 833 mm (32.8 in) stock extended/630 mm (24.8 in) stock folded |

| Barrel length | 251 mm (9.9 in) |

| Cartridge | 9×19mm Parabellum |

| Action | Straight blowback, open bolt |

| Rate of fire | 500–550 rounds/min |

| Muzzle velocity | 400 m/s (1,312 ft/s) |

| Effective firing range | 100–200 m |

| Maximum firing range | 250 m |

| Feed system | 32-round detachable box magazine, 64-round with dual magazines |

| Sights | Hooded front blade |

Design

The MP 40 submachine guns are open-bolt, blowback-operated automatic arms. The only mode of fire is automatic, but the relatively low rate of fire permits single shots with controlled trigger pulls. The bolt features a telescoping return spring guide which serves as a pneumatic recoil buffer. The cocking handle was permanently attached to the bolt on early MP 38s, but on late-production MP 38s and MP 40s, the bolt handle was made as a separate part. It also serves as a safety by pushing the head of the handle into one of two separate notches above the main opening; this action locks the bolt in either the cocked (rear) or uncocked (forward) position. The absence of this feature on early MP 38s resulted in field expedients such as leather harnesses with a small loop that were used to hold the bolt in the forward position.

The MP 38 receiver was made of machined steel, but this was a time-consuming and expensive process. To save time and materials, and thus increase production, construction of the MP 40 receiver was simplified by using stamped steel and electro-spot welding as much as possible. The MP 38 also features longitudinal grooving on the receiver and bolt, as well as a circular opening on the magazine housing. These features were eliminated on the MP 40.

One feature found on most MP 38 and MP 40 submachine guns is an aluminum, steel, or Margolit (a variation of Bakelite) resting bar under the barrel. This was used to steady the weapon when firing over the side of open-top armored personnel carriers such as the Sd.Kfz. 251 half-track. A handguard, also made of Margolit, is located between the magazine housing and the Margolit pistol grip. The barrel lacked any form of insulation, which often resulted in burns on the supporting hand if it was incorrectly positioned. The MP 40 also has a forward-folding metal stock, the first for a submachine gun, resulting in a shorter overall weapon when folded. However, this stock design was at times insufficiently durable for hard combat use.

Reviews

There are no reviews yet.