Description

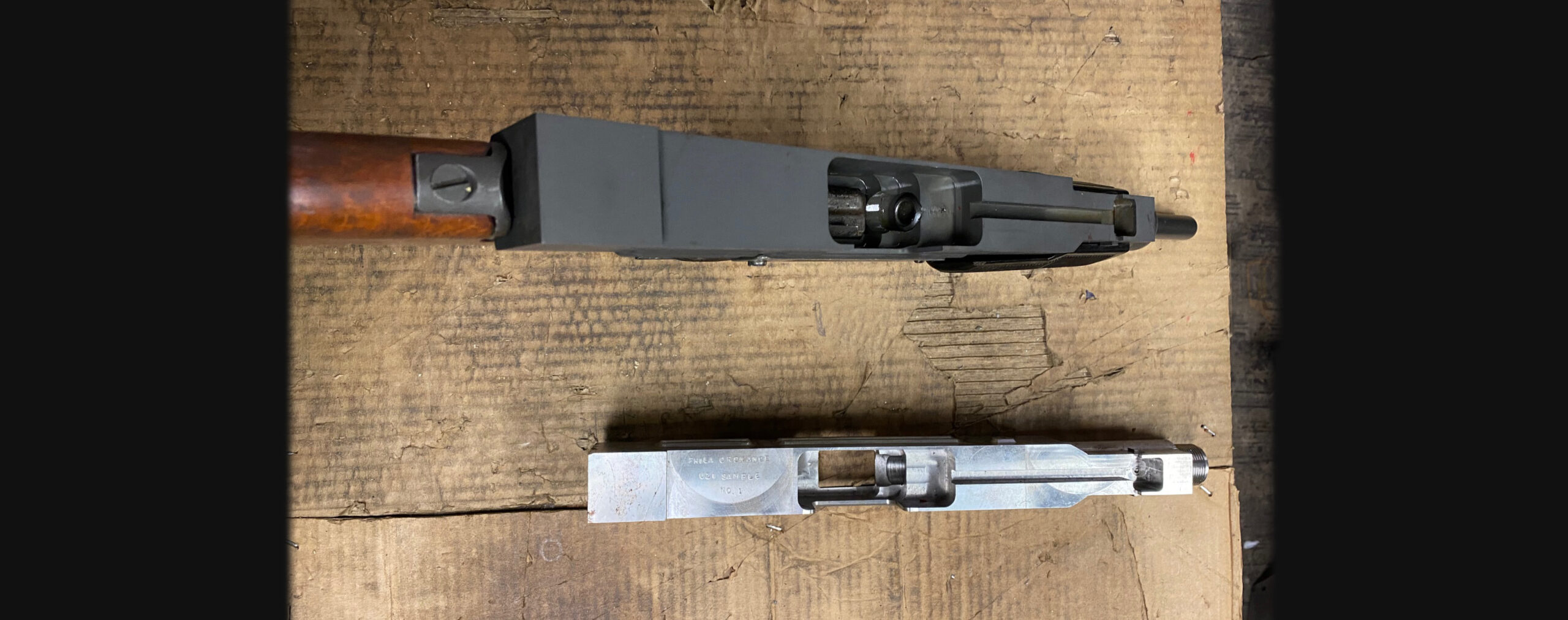

These display receivers have been machined from a bar of 1018 cold rolled steel. These display receivers were made from the help of Philadelphia Ordnance and are exactly reproductions are their receivers from the early 2000’s.

NO FFL or paperwork is required.

The machining operations present are:

- forward end threaded for barrel sleeve

- circular barrel channel machined from threaded forward end to exposed feed ramp

- forearm mounting lugs and bayonet mount machined

- ejection port machined

- interior area machined above the magazine well opening and feed ramp on bottom (area approximately 3-1/2” x 1-1/2”)

- channel approximately 4-3/8” x 5/16” machined into upper forward area (cocking lever guide)

- cavity approximately 5/8” x 3/4” x 1/2” machined at the forward shoulder of the cocking lever guide channel

- lug machined for trigger housing takedown pin

- sear openings partially machined in bottom

- solid receiver section behind magazine well opening

- rectangular hole approximately 1/2 x 5/16x 1/4 ” machined into near lower rear edge

- circular hole approximately 1/2” in diameter and 1/2” deep machined into rear wall

Operations that would define these display receivers as a gun:

- The reminding bolt channel would have to be machined away.

- Front and rear sights would have to be added.

Background

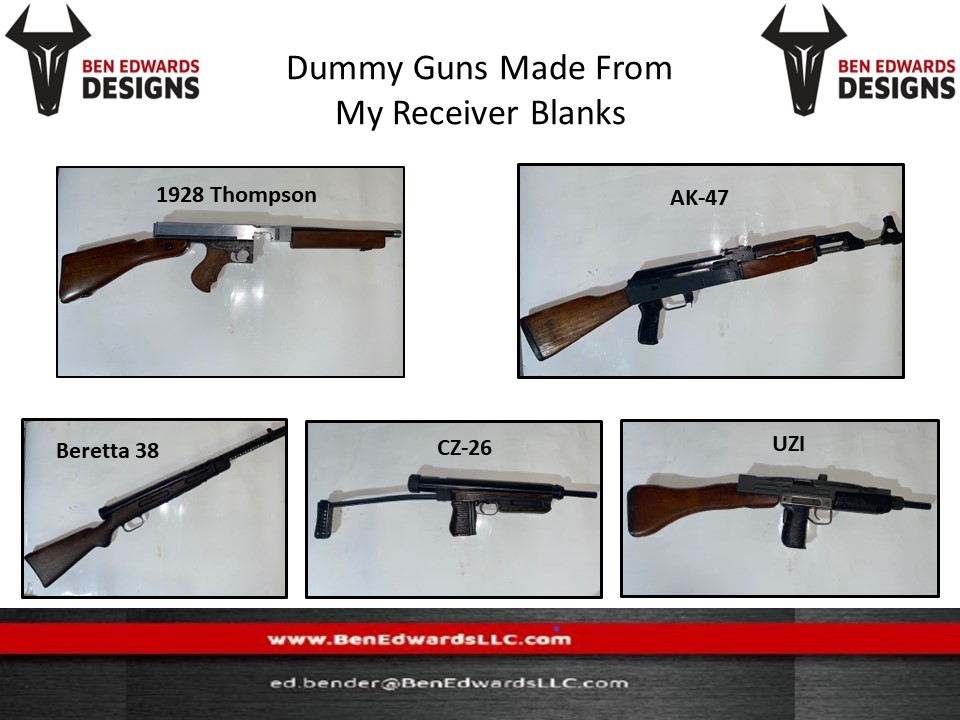

The Uzi , Ūzi; officially cased as UZI) is a family of Israeli open-bolt, blowback-operated submachine guns and machine pistols first designed by Major Uziel “Uzi” Gal in the late 1940s, shortly after the establishment of the State of Israel. It is one of the first weapons to incorporate a telescoping bolt design, which allows the magazine to be housed in the pistol grip for a shorter weapon.

The Uzi prototype was finished in 1950. It was first introduced to Israel Defense Forces (IDF) special forces in 1954, and the weapon was placed into general issue two years later. The IDF supplied Uzis to rear-echelon troops, officers, artillery troops and tank crews, as well as a frontline weapon by elite light infantry assault forces.

The Uzi has been exported to over 90 countries. Over its service lifetime, it has been manufactured by Israel Military Industries, FN Herstal, and other manufacturers. From the 1960s through to the 1980s, more Uzi submachine guns were sold to more military, law enforcement and security markets than any other submachine gun ever made.

Technical Information

| In service | 1954–present |

| Designer | Uziel Gal |

| Designed | 1950 |

| Manufacturer | Israel Military Industries |

| Israel Weapon Industries | |

| Licensed by: | |

| FN Herstal | |

| Norinco | |

| Z111 Factory | |

| Lyttleton Engineering Works | |

| RH-ALAN | |

| Group Industries | |

| Produced | 1950–present |

| No. built | 10,000,000+ |

| Variants | See Variants |

| Specifications | |

| Mass | 3.5 kg (7.72 lb) |

| Length | 445 mm (17.5 in) stockless |

| 470 mm (18.5 in) folding stock collapsed | |

| 640 mm (25 in) folding stock extended | |

| Barrel length | 260 mm (10.2 in) |

| Cartridge | .22 LR |

| .41 AE | |

| .45 ACP | |

| 9×19mm Parabellum | |

| 9×21mm IMI | |

| Action | Blowback, open bolt |

| Rate of fire | 600 rounds/min |

| 950 rounds/min Mini Uzi | |

| 1200–1500 rounds/min Micro Uzi | |

| Muzzle velocity | 400 m/s (1,300 ft/s) (9mm) |

| Effective firing range | 200 m |

| Feed system | 10-round box magazine (.22 and .41 AE) |

| 12-, 16-, or 22-round box (.45 ACP) | |

| 20-, 25-, 32-, 40-, or 50-round box (9×19mm Parabellum) | |

| Sights | Iron sights |

Design

The Uzi uses an open-bolt, blowback-operated design, quite similar to the Jaroslav Holeček-designed Czech ZK 476 (prototype only) and the production Sa 23, Sa 24, Sa 25, and Sa 26 series of submachine guns. The open bolt design exposes the breech end of the barrel, and improves cooling during periods of continuous fire. However, it means that since the bolt is held to the rear when cocked, the receiver is more susceptible to contamination from sand and dirt. It uses a telescoping bolt design, in which the bolt wraps around the breech end of the barrel. This allows the barrel to be moved far back into the receiver and the magazine to be housed in the pistol grip, allowing for a heavier, slower-firing bolt in a shorter, better-balanced weapon.

The weapon is constructed primarily from stamped sheet metal, making it less expensive per unit to manufacture than an equivalent design machined from forgings. With relatively few moving parts, the Uzi is easy to strip for maintenance or repair. The magazine is housed within the pistol grip, allowing for intuitive and easy reloading in dark or difficult conditions, under the principle of “hand finds hand”. The pistol grip is fitted with a grip safety, making it difficult to fire accidentally. However, the protruding vertical magazine makes the gun awkward to fire when prone. The Uzi features a bayonet lug.

Reviews

There are no reviews yet.