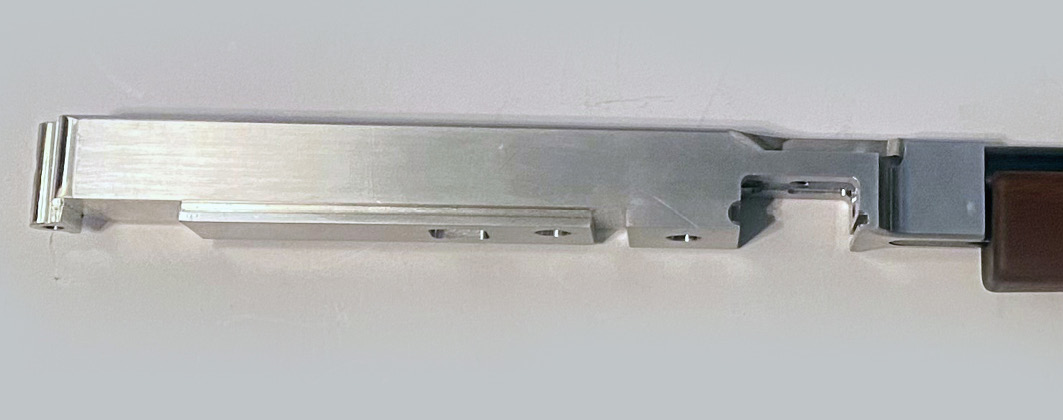

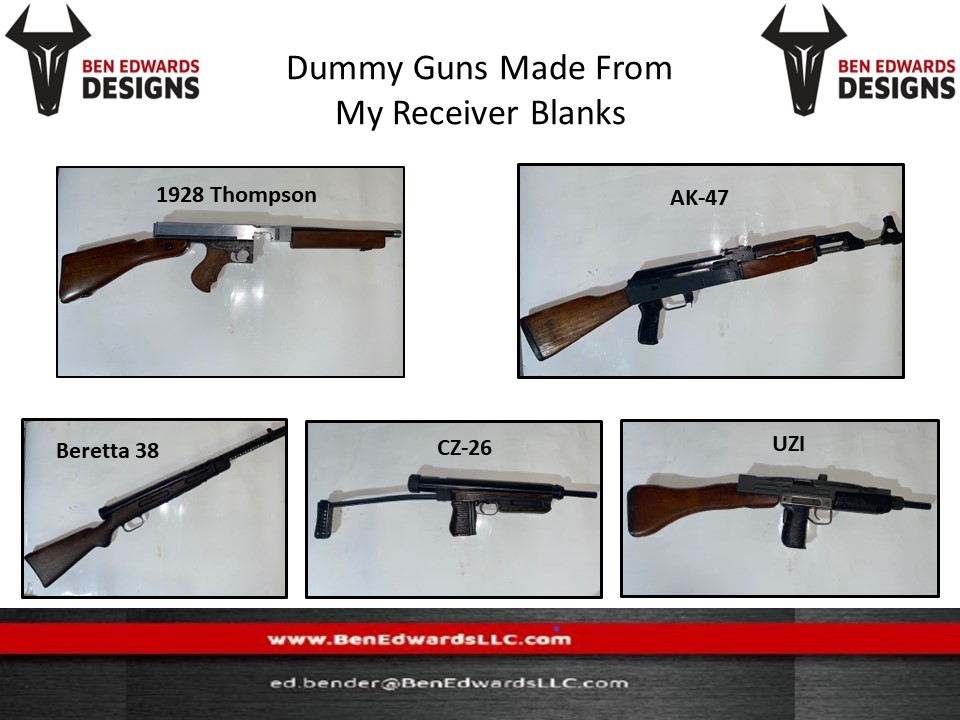

Description

This 6061 Aluminum 1928 Thompson receiver is the highest quality dummy receiver on the market. This receiver is threaded for the barrel and has precisely machined rails to fit the trigger frame.

NO FFL or paperwork is required.

\

Background

Brigadier general John T. Thompson was the original developer of the Thompson submachine gun, who spent most of his career in the ordnance department of the U.S. Army. He envisioned it as being a fully automatic rifle in order to replace the bolt-action service rifles then in use (such as the American M1903 Springfield).

Brigadier general Thompson came across a patent issued to the American inventor John Bell Blish in 1915, while searching for a way to allow his weapon to operate safely without the complexity of a recoil or gas-operated reloading mechanism. Blish’s design (then known as the Blish Lock) was based on the supposed adhesion of inclined metal surfaces under pressure. Thompson gained financial backing from the businessman Thomas F. Ryan and proceeded to found a company, which he named the Auto-Ordnance Company, in 1916, for the purpose of developing his new “auto rifle”.

The Thompson was primarily developed in Cleveland, Ohio. Its principal designers were Theodore H. Eickhoff, Oscar V. Payne, and George E. Goll. By late 1917, the limits of the Blish Lock were discovered (which is essentially an extreme manifestation of static friction), and, rather than the firearm working as a locked breech, the weapon was instead designed to function as a friction-delayed blowback action. It was found that the only cartridge currently in service suitable for use with the new lock was the .45 ACP. General Thompson envisioned a “one-man, hand-held machine gun” chambered in .45 ACP to be used as a “trench broom” for the ongoing trench warfare of World War I. Oscar V. Payne designed the new firearm along with its stick and drum magazines. The project was titled “Annihilator I”. Most of the design issues had been resolved by 1918; however, the war ended two days before prototypes could be shipped to Europe.

Technical Information

| In service | 1938–1971 (U.S. military) | |

| Used by | See Users | |

| Production history | ||

| Designer | John T. Thompson | |

| Designed | 1917–1920 | |

| Manufacturer | Auto-Ordnance Company (originally) | |

| The Birmingham Small Arms Company Limited | ||

| Colt | ||

| Savage Arms | ||

| RPB Industries | ||

| Produced | 1921–1945 | |

| No. built | Approximately 1.75 million of all variants including: | |

| 562,511 M1928A1 | ||

| 285,480 M1 | ||

| 539,143 M1A1 | ||

| Variants | See Variants section | |

| Specifications | ||

| Mass | 10.8 lb (4.9 kg) empty (Thompson M1928A1) | |

| 10 lb (4.5 kg) empty (Thompson M1A1) | ||

| Length | 33.7 in (860 mm) (M1928A1 with compensator) | |

| 31.9 in (810 mm) (M1/M1A1) | ||

| Barrel length | 10.52 in (267 mm) | |

| 12 in (300 mm) (with Cutts compensator) | ||

| Cartridge | .45 ACP (11.43×23mm) | |

| 10mm Auto (Limited quantity of FBI conversions) | ||

| Action | Blowback, Blish Lock | |

| Rate of fire | 700–800rpm (M1928) | |

| 600-700rpm (M1A1) | ||

| Muzzle velocity | 935 ft/s (285 m/s) | |

| Effective firing range | 164 yds (150 m) | |

| Feed system | 20 or 30 round box magazine, 50 or 100 round drum magazine[15] (M1 and M1A1 models do not accept drum magazines) | |

Operating characteristics

Early versions of the Thompson, the Model 1919, had a fairly high cyclic rate of fire, as high as 1,200 rounds per minute (rpm), with most Model 1921s at 800 rpm. This rate of fire, combined with a rather heavy trigger pull and a stock with an excessive drop, increases the tendency for the barrel to climb off target in automatic fire. In 1927, the U.S. Navy ordered 500 Thompsons but requested a lower rate of fire. Thompson requested Payne to develop a method of reducing the cyclic rate of fire. Payne then replaced the actuator with one that was heavier, and replaced the recoil spring with one that was stiffer; the changes reduced the rate of fire from 800 to the 600 rpm of the U.S. Navy Model 1928. Later M1 and M1A1 Thompsons averaged also 600 rpm. Compared to more modern submachine guns, the Thompson is quite heavy, weighing roughly the same as the contemporary M1 Garand semi-automatic rifle, and requires a lot of cleaning. This was one of the major complaints about the weapon by U.S. Army personnel to whom it was issued.

Although the drum magazine provided significant firepower, in military service it was found to be overly heavy and bulky, especially when slung on the shoulder while marching. The M1928A1 Thompson drum magazine was rather fragile, and cartridges tended to rattle inside it, producing unwanted noise. For these reasons, the 20-round and later 30-round box magazines soon proved most popular with military users of the M1928A1, and drum compatibility was not included in the design of the wartime M1 and M1A1 models. The Thompson was one of the earliest submachine guns to incorporate a double-column, staggered-feed box magazine design, which undoubtedly contributed to the gun’s reputation for reliability. In addition, the gun performed better than most after exposure to rain, dirt, and mud.

The selective-fire (semi or fully automatic) Thompson fires from the “open bolt” position, in which the bolt is held fully to rearward by the sear when cocked. When the trigger is depressed, the bolt is released, traveling forward to chamber and simultaneously fire the first and subsequent rounds until either the trigger is released or the ammunition is exhausted. This eliminates the risk of “cook-off”, which can sometimes occur in closed-bolt automatic weapons.

Reviews

There are no reviews yet.